In my recent blog post “How enterprise software vendors can support supply chain segmentation” I talked about the opportunity to create multiple supply chains within the same physical flow of products, to better align the attributes of the supply chain with the competitive advantages and demand profile for each group of products offered to the market. An example of two different approaches sharing one common supply chain could be:

- A range of fast moving commodity products delivered the same day the order is placed.

- A range of tailored products manufactured and delivered to specification within 3 days.

The benefit of the first example is quick deliveries, with high service levels at a competitive price. The second example shows great variant flexibility with a price premium attached. You can compare this with buying a lunch. The first example is similar to a visit to McDonalds. A limited range is delivered at a low price within minutes. The second example is similar to the offering of an á la carte restaurant. They offer a wide menu to choose from, but you have to wait for the food to arrive and you expect to pay a premium price.

From an industry point of view the first example demonstrates the efficient supply chain required to provide products profitably to a price sensitive marketplace. Since short delivery time is a competitive advantage, manufacturing needs to start before the actual customer demand is present. Manufacturing is planned based on a sales forecast in combination with the current stock level. Production batch sizes are optimized to minimize total overall cost. Operating in this mode is usually called make-to-stock (MTS). The benefits of a make-to-stock strategy are low unit cost and short delivery lead-times. The main disadvantage is the risk of high stock levels and slow inventory turns in case customer demand does not occur as expected.

The second example illustrates a flexible supply chain tailored to meet specific customer requirements. Since the demand for each possible finished goods is very un-predictable these products are finalized once the customer order has been received. This type of planning is called make-to-order (MTO). The main advantage is the ability to supply according to exact customer specification without running the risk of excess inventories. The drawback is that the unit cost will be higher for two reasons. First, acceptable lead-times will require some over capacity in manufacturing creating a lower overall resource utilization. Secondly, the batch sizes will be determined by the size of the customer order.

Mixed mode manufacturing means that you combine make-to-stock (MTS) and make-to-order (MTO) in one common supply chain. The value proposition of this is that you can strike a balance between efficiency and flexibility across the product range by assigning different supply models to different products. With mixed mode manufacturing it is the possibility to offer your customers the quick response and low prices offered by McDonalds in parallel with the somewhat more unique experience offered by an á la carte restaurant.

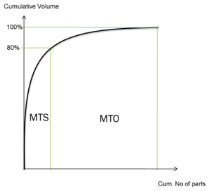

A starting point when considering a mixed-mode supply model is to analyze how the companies demand for products is distributed. The result will usually be that a small amount of all products offered constitute for a large portion of the total volume. Figure 1 below illustrates this situation:

The few fast moving MTS parts face a smooth, predictable demand and are planned based on forecasted sales. They are manufactured in the most efficient way considering the trade-off between set up costs versus inventory holding cost. The slow moving MTO parts have a much more intermittent and unpredictable demand. It means that it will be very expensive to stock keep each possible variant just in order to be able to ship once the customer demand is present. This is when a combination of make-to-stock and make-to-order can yield significant advantages.

The level of the Bill of Material from which production is initiated is usually called the “Point of Postponement” or “Customer Decoupling Point”. This is the point in the supply chain where forecast driven supplies meet the demand pulled by actual customer demand.

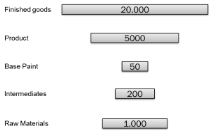

My personal experience from implementing mixed-mode manufacturing systems is from the process manufacturing industry. Figure 3 below shows an example from the paint manufacturing industry where the number of possible variants usually increases dramatically the closer to the finished goods level you get.

This is a typical “X” shaped bill of material. A small number of base paints explode into a multitude of potential colors and glosses. When this then is combined with the different packaging options the number of finished goods items turns into a very high number. Out of these potential finished goods items there are just a small fraction that has a steady, predictable demand. All other variants are sold in smaller volumes. It would be very expensive to stock keep all these based on an uncertain forecast. Since everything the company sells actually is based on any of the just 50 Base Paints shown in the picture this is the perfect place for the point of postponement. The sum of the demand from all finished goods variants is predictable and the base paints can be produced and put into stock efficiently.

This also assumes that the downstream lead-time, from base paint to finished goods is acceptable. Typically for this industry the lead-times for raw materials can be quite long. Also processing times for some intermediates can stretch for a couple of days or sometimes weeks. From this level to finished goods lead-times can be kept short and usually depend more on potential capacity shortages than actual processing times.

In order to implement this strategy for a process manufacturing company it is important to have an enterprise software system such as IFS Applications that can support not only industry specific requirements for example formulations and multiple units of measure, but also mixed mode manufacturing. This includes a combination of traditional, forecast driven make-to-stock and in parallel typical make-to-order attributes such as a flexible option to position the point of postponement individually for different groups of products. In addition to this functionality such as material pegging, actual cost tracking, multi-level available and capable to promise as well as support for configure-to-order are often useful and/or required to implement mixed mode manufacturing.

In my next blog post I will talk about another interesting opportunity in the area of supply chain segmentation, differentiated inventory planning. This is a method to find an optimal balance between service levels and supply chain cost by using different inventory planning policies for different groups of products offered to the market.

Learn more about Manufacturing Solutions at ifs.com.

Do you have questions or comments?

We’d love to hear them so please leave us a message below.