Trying to plan the unplannable with DDMRP (Demand Driven Material Requirements Planning). Following on from my previous blog about the history of DDMRP, I wanted to dig deeper into the various stages of setting up DDMRP and why you might consider it.

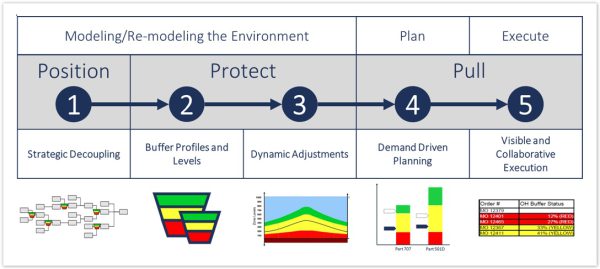

But let’s have a quick recap on the stages of DDMRP before going any further:

- Position: Bills of materials are examined to identify strategic items – materials or components – at critical points within the structures. In an adaption of the Theory of Constraints method, in which critical resources known as “constraints” determine production limitations, these key materials must be the focus of control above all other components.

- Protect: Availability of these critical items is also ensured by using inventory as a buffer. But this buffer inventory is not deployed as part of the initial MRP (Material Requirements Planning) planning formula; rather, it is replenished dynamically as needed.

- Pull: Buffer inventory is managed through an innovative pull technique that continually monitors inventory levels and uses visual cues to maintain the buffer within a specified range.

In this blog, I’d like to take a closer look at the first stage of DDMRP –

Position

You don’t have to move all components to DDMRP. It’s not a case of choosing either MRP or DDMRP, they can be used together seamlessly. It’s possible to select components individually, depending on how critical they are or where they are in the Bill of Materials.

The ideal parts for DDMRP are those where you either have too little or too much. And you’ll know exactly what I mean by that – there’re the ones always running out of stock or where too much stock is being held, and no amount of careful planning seems to fix these conditions! Consumable parts are a good starting point for Manufacturers who want to ‘test’ DDMRP and gain confidence in the data calculated for this new way of planning. Another potential group of components are the options in a Configure to Order (CTO) assembly. These are traditionally planned and procured by planners/buyers who ‘know’ what the stock should be. Setting these to DDMRP takes out the reliance on that knowledge. Components that are already set outside MRP, via reorder point planning and safety stock levels, can be moved to DDMRP to take away the constant review and maintenance of these levels.

Priority

DDMRP has another benefit by giving a clear priority to which components need to be ordered first. Imagine the scenario where a program or project has slipped and there are a lot of purchase orders that need to be placed. Traditional MRP will create a priority based on the due date. However, the components that come to the top of this list are the long lead items and it’s possible that some components need to be ordered sooner, due to higher daily usage. DDMRP has this data and will prioritize the Purchase Orders, to meet the production plan.

Once these components have been moved to DDMRP planning more can be considered. Looking at the build of a product through the assembly levels will show assemblies that are common or a constraint. Perhaps they can only be assembled on one machine, or the process time is dictated by the process itself and cannot be sped up. Turning these critical resources over to DDMRP can reduce the risk of not having stock when it’s needed by having a buffer that’s able to absorb fluctuations in assembly. Where assemblies are controlled by DDMRP the stacked, or cumulative, product lead-time is disconnected. This means that the lead-time becomes unprotected, which can reduce the overall product lead-time.

In my opinion this is the most difficult concept to grasp when using DDMRP. If you’ve always used the MRP logic, it doesn’t make sense that producing something based on proven capacity and forecast, halfway in a build structure, will shorten overall build lead times. DDMRP considers the average daily usage based on past actual numbers achieved and the demand upstream, protecting the component with a buffer that’s ‘pulled’ by the demand coming from above.

Making a change after years of doing things a particular way is daunting. However, once you’ve taken the first step, you’ll soon see the benefits.

Final Thoughts

DDMRP is built for people not perfection.

Selecting the parts for DDMRP is not easy if you’re used to planning top-down through a Manufacturing Bill of Materials. But once you’ve moved a few parts to DDMRP and planned them for a while, the results will encourage you to move even more!

My next Blog will cover what DDMRP looks like to the planner and what the different colored zones mean.

If this blog has been of interest, I would like to expand on DDMRP and show how it works and how it could help your business. Please let me know what you think in the comments box below or feel free to reach out via LinkedIn.

Discover more about IFS for Manufacturing https://www.ifs.com/industries/manufacturing/