MRP was invented in the fifties, computerized in the sixties and later became the dominating planning principle in the manufacturing industry. Today you find an MRP calculation being part of any ERP system available on the market.

As the years have gone by since MRP was introduced have seen a shift from an era with local manufacturing of products with long lifecycles for a local market to today’s global competing supply networks. This has created new challenges that MRP is simply not up to. The result is that many businesses operate in a reactive mode. Products are made to an uncertain forecast, which inevitably leads to a mix of shortages and overstocks. Promotions and price cuts are used to drive out excess inventories. Top line and customer loyalty is hurt by lost revenue, and bottom line suffers from shrinking margins.

DDMRP was developed in response to this as an extension to MRP designed to deal with today’s reality. It will support the transition to a proactive state where companies position stock buffers to cut lead-times and ultimately become truly demand driven.

The concepts of Demand Driven MRP (DDMRP) was defined by and first published in the third edition of “Orlicky’s Material Requirements Planning” in 2011. Today the definitive reference on the subject is “Demand Driven Materials Planning (DDMRP), Version 2” by Carol Ptak and Chad Smith.

Why MRP doesn’t work

Which are the factors that makes MRP struggle and how do we discover the symptoms?

A trend that we have seen for at least 40 years is that companies shorten product lifecycles to bring innovation to market and stay ahead of the competition. Another, more recent trend is a more diversified, personalized offering to better meet individual preferences and criteria’s. To cut costs companies manufacture in low cost areas or outsource for resource sharing and benefits of scale, which stretches lead-times and sacrifice flexibility.

Problem is that what the products gain is the supply chain’s pain. Making more attractive products at a lower unit cost have created supply chains where the forecast error is higher than ever before at a point when the ability to absorb variation is lost in the pursuit for benefits of scale and low unit cost.

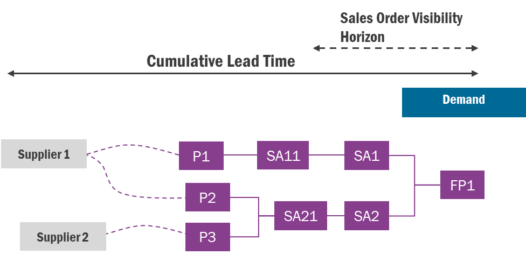

MRP planning by design assume that future demand needs to be known one cumulative lead-time ahead. Longer lead-times caused by outsourcing means that the decision to purchase components and manufacture sub-assemblies must be taken long before the finished goods is sold. This make planners addicted to forecasts. The further out into the future they must rely on forecasts, the higher the error will be. MRP nets to zero, any internal or external variation will cause a change of plans.

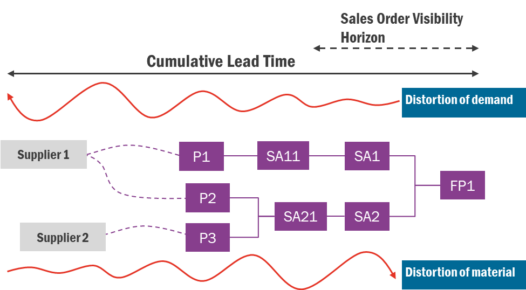

Problem is that with the network complexity and all dependencies, variation happens all the time. This is probably why people talk about the MRP being “nervous” or “sensitive”. It is not really – it is just not designed for the circumstances it is used for. The result is that all the distortion will cause the supply chain to oscillate, with frequent overstocks and shortages as a result. This is what is often referred to as the bullwhip effect.

How can DDMRP help?

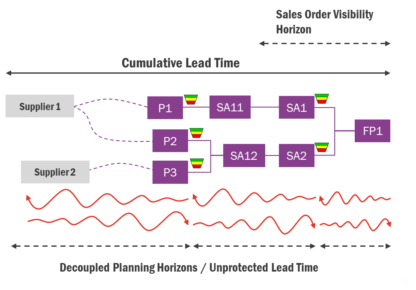

DDMRP introduces stock buffers that will decouple demand from supply and make them independent. The result is two-fold. Downstream, on the demand side of the buffer it will provide availability for consumers (materials or customers). If the buffer can fulfill its mission, this means that the lead-time for all parts that are constrained by the buffered part now decrease. The part of the cumulative lead-time that remains is called unprotected lead-time (ULT), or for a fancier expression; decoupled planning horizon.

Upstream, on the supply side of the buffer, it will act as a wave-breaker. It does this by aggregating and absorbing demand variation. This will protect suppliers (internal resources or external suppliers) and prevent bullwhips.

In the previous section we talked about how MRP per definition depend on forecasts one cumulated lead-time into the future, how planners must rely on forecasts and that any type of distortion (a delayed component, a quality problem in manufacturing, a customer that cancel an order) is impossible to deal with on the short term.

DDMRP buffers will decouple the supply network into smaller sections. The buffers will prevent variation from amplify up and down the supply network. They will also cut lead-times, ultimately to the extent that planners can rely on the best demand signal of all, actual orders, to support their decisions.

By this I hope that you are convinced about the relevance of DDMRP. The next question is – how can we make it work? We need a framework of tools and methodology to successfully implement DDMRP. In my next blog post we will have a closer look at the five steps that define DDMRP.

Do you have questions or comments?

We’d love to hear them so please leave us a message below.

Follow us on social media for the latest blog posts, industry and IFS news!

LinkedIn | Twitter | Facebook | Google+

Thushara

Could you please let me know, what is the tool that we can use for production planning such as product structure that contains more than 8 shop order levels,

Vee Baker

I have passed your question to Jakob – Vee