Meet our guest author, Ted Rohm, Senior ERP Analyst at Technology Evaluation Centers (TEC)

Ted Rohm is a Senior ERP Analyst at Technology Evaluation Centers (TEC). Ted covers the areas of enterprise resource planning (ERP), enterprise asset management (EAM), configure price quote (CPQ), supply chain management (SCM) and IT service management (ITSM), with a particular expertise in manufacturing. He has over 20 years of experience in large-scale selection, design, development and implementation projects, primarily in the biotech/pharma industry.

Managing assets has always been an important component of the smooth operations of companies across a wide range of industries. Manufacturers need to ensure that all production equipment is operating effectively, utilities providers must ensure proper care and maintenance of pipes and transmission lines, and governments need to manage transportation infrastructure to name a few. At the same time, companies need to manage everyday business operations including selling their product or service and paying their bills.

In order to manage their assets and critical business operations, companies often need to invest in two separate software applications. One is an enterprise resource planning (ERP) system and the other is an enterprise asset management (EAM) system. The ERP system manages business operations and the EAM system manages all the monitoring and operations of the asset. Technological advances, along with the associated price drop for smart products being developed for the Internet of Things (IoT), now make it possible to monitor almost any asset in real-time from nearly any location across the globe. The use of EAM software in one form or another is becoming increasingly critical for all industries in order to succeed in what is being called the fourth industrial revolution.

Many companies struggle to decide whether to purchase an EAM system or an ERP system. Since both of these purchases can be significant and costly, an organization might try to decide between one or the other. Unfortunately, most ERP systems lack the features necessary to properly support a company’s need to manage its assets and EAM systems were definitely not built to meet broader enterprise business requirements.

ERP and EAM systems are made to manage different areas

ERP systems are built to support an organization’s financials, manufacturing, sales and human resources operations. They can also manage the basic financial requirements for assets, such as asset costs and depreciation. But most ERP solutions will not manage even relatively simple asset components makeup (such as breaking down the components of a door cutting machine into the individual routers and bits) or other capabilities found in an EAM system.

EAM systems, on the other hand, are built to help manage assets ranging from the simplest to the most complex (e.g., linear assets that are set up to monitor the entire length of a major highway). The EAM system will support these complex components, track the location and status of the assets in real time, schedule work orders to maintain and fix the assets and manage the storage of spare parts required to service the assets. These capabilities are not found in typical ERP systems.

EAM and ERP integration issues

If a company decides to purchase separate EAM and ERP solutions, integration between them is an important consideration. The issues that must be considered include master data synchronization and transaction integration. In addition, business processes must be evaluated to determine whether the ERP or EAM solution is better suited to be the system of record for a particular transaction or asset type.

There will be master data to keep in sync, which will include objects such as assets, purchasing accounts and inventory items. The two systems will have to communicate with each other using a programmatic interface, which means the underlying architecture of the two systems must be complimentary or adaptable to ensure they can work together.

Last but not least, the system in which a particular transaction will be processed needs to be mapped out in advance. Ideally, all the EAM-related transactions can be managed in the EAM system to allow for optimal monitoring, performance and uptime of the assets.

The IoT and other technologies changing the asset game

The connectivity and intelligence provided by IoT solutions are creating tremendous opportunities for better management of assets. The collection of data from within machinery and other assets allows for such efficiencies as predictive maintenance and smart metering management. These billions of smart devices are also changing business models themselves—companies are able to bill for jet engine hours of service instead of for the jet engine itself, for example. Rolls-Royce led the way with its “power-by-the-hour” model which charges airlines for the time used during flight.

IoT is not, however, the only technology that is being used to better track and manage assets. We see drones being used to monitor assets, such as monitoring oil pipelines in Canada and oil platforms in the Bering Sea, as well as inspecting bridges and infrastructure without endangering the inspector.

All this means that there is more detailed and current data, which allows for better management of the assets via prescriptive analytics. The proliferation of newer technology shows no bounds and will continue to make asset management easier, faster, cheaper, less dangerous and more precise.

The Ideal: A single integrated ERP and EAM solution

The ideal system for an asset-intensive organization is an ERP system with extensive EAM capabilities: a system built from the ground up to manage not only basic business functions but also assets and their maintenance. The majority of ERP systems on the market were built first and foremost to cater to the manufacturing and services industries, not asset-intensive ones. This is true across tiers, from the tier one solutions offered by SAP, Oracle, Microsoft and Infor, down to tier two solutions from Deltek, EPICOR, Glovia, NetSuite and others.

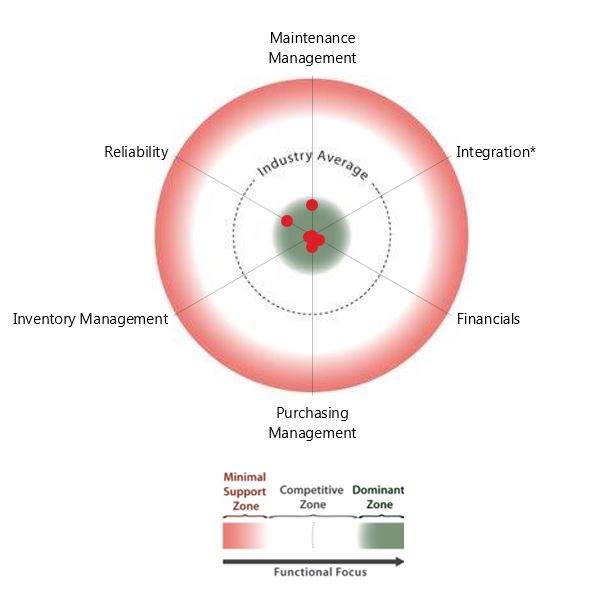

The one ERP system that stands out as being originally built around asset monitoring and maintenance is offered by IFS Applications. IFS is one company whose EAM capabilities, delivered part and parcel of the integrated ERP solution, receive top marks from analyst firms including TEC. The graph below is the TEC Focus Indicator which shows how IFS Applications stacks up against the average industry solution in the EAM market space.

Figure 1. TEC Focus Indicator comparing IFS Applications against the industry average.

The TEC Focus Indicator presents the results of benchmarking IFS Applications against an industry average. TEC calculates the industry average for a given software market space based on product data from real-world software solutions, scoring solution support for hundreds to thousands of features and functions. The Industry Average circle in the middle of the graph is a normalized representation of the average of the scores. IFS scores in the Dominant Zone for all the critical capabilities modules of an EAM solution.

Of course, a focus on EAM functionality is not the only consideration when deciding on an ERP solution. An impartial software analysis firm like TEC can help you define your needs and find the best solution to support your evolving business.

Learn more about ERP Solutions at ifs.com.

Do you have questions or comments about EAM and ERP?

We’d love to hear them so please leave us a message below.

SAP Business One India

Great to read your blog. It is very helpful to me for knowing new things

SAP Business One

Thanks for sharing such a great informative blog… Keep it up.

taishadarelene

The post is absolutely fantastic! Lots of great information and inspiration both of which we all need! Also like to admire the time and effort you put into your blog.

ERP software development company in chennai

taishadarelene

This is one of the best article in this blog,thanks for sharing information about erp in google chrome browser,keep it up…

ERP software development company in chennai

taishadarelene

The post is absolutely fantastic! Lots of great information and inspiration both of which we all need! Also like to admire the time and effort you put into your blog.

Narendran

Iam sure that there will be a lot of folks will benefit from your content, so please keep up your act always team.

Umakanta

Great article clarifying the difference between ERP and EAM which is mostly confusing. Thanks a lot.

Monica

Such a great information. It’s not easy to do, but thanks for this help. Thanks and keep on sharing.

arketing-services-chennai.php”>smo companyin chennai

crm software development company in chennai

professional web design company in chennai

Apple infoway

Best enterprise resource planning company in chennai,india.

Best enterprise resource planning software company in chennai,Best enterprise resource planning software company in india,erp software companies in india,chennai

Sarah Smith

Thanks for your information on ERP services! I think my business needs to use ERP systems. I will start looking for a quality company.

ERP Software For Food And Beverage Industry

Thanks for the great article learned a lot from this one

Rahul Jain

Such a great information. Keep posting about ERP & SAP!