Artificial intelligence (AI). Internet of Things (IoT). Augmented reality (AR). These are the technologies companies in the industries IFS serves want to implement because they can transform their businesses. These two- and three-letter acronyms (TLAs) are what most of us think about when someone utters the words ‘digital transformation’.

While AI, IoT and AR are hot now, have there been other equally disruptive technologies that have now reached a point of maturity in most companies? Can we find evidence of that disruption? With a new IFS study, yes, we can.

Changing manufacturing business models

Changing manufacturing business models

Manufacturing modes including make-to-stock and make-to-order are like the DNA of manufacturing. In recent years, that DNA has gone through a remarkable evolutionary phase.

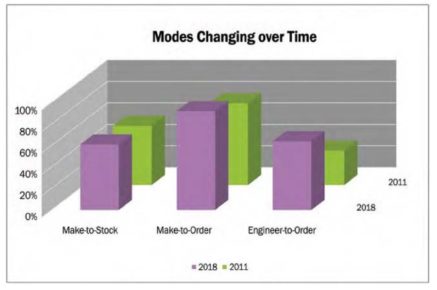

According to new primary research from IFS, manufacturers are now more likely to make or engineer products to order than make them to stock.

Make-to-stock (MTS) business models are historically more associated with the manufacture of goods with long lead times and/or predictable demand. In contrast, to-order business models like make-to-order (MTO) and engineer-to-order (ETO) are historically more associated with products that have a short manufacturing lead time and/or unpredictable demand—like capital equipment or industrial manufacturing.

However, the IFS data shows that to-order business models have infiltrated industries including food and beverage, with 43 percent of food and beverage manufacturers in 2018 reporting being involved in engineering products to customer orders, perhaps as contract manufacturers. A surprising 80 percent of food and beverage companies report making products to order, which suggests a very sophisticated supply chain and agile manufacturing practice capable of responding seamlessly to inbound demand signals.

“The MTS business model is quickly becoming a disadvantage for many traditional MTS manufacturers,” IFS Chief Technology Officer, North America, Rick Veague said. “Rapidly changing consumer tastes and preferences make forecasting difficult and this increases the probability that the stock you’re manufacturing today becomes tomorrow’s excess inventory. By more closely aligning firm demand with manufacturing response, inventory levels can be optimized and costs reduced.”

Underlying technology

While businesses have been under economic pressure to optimize inventory levels and cut costs, what technology has enabled them to make such a drastic change in business model in a relatively short space of time? The obvious answer is enterprise resource planning (ERP) software. ERP has been widely available for decades, originating with its predecessor, materials requirements planning (MRP). In the last seven years, however, we have seen companies continue to replace legacy systems, upgrade and roll out new functionality for existing software solutions and replace standalone and siloed systems. The increasing standardization on a single system of record alone makes a business more responsive and able to handle to-order business models. Only ERP offers effective available-to-promise visibility and the real-time control necessary for MTO business models. More advanced ERP also can be designed specifically to handle ETO, with an integrated workflow from customer relationship management (CRM) to engineering to purchasing and manufacturing. This enables a manufacturer to communicate design changes not only to the customer, but also to purchasing and manufacturing groups to avoid work being performed on outdated revisions. To-order requires more agile operation and 21st century ERP is beginning to deliver that agility.

Some companies may also be increasingly able to leverage ERP from mobile devices. This is critical in the shift from MTS to MTO and ETO because it speeds up approval cycles and other forms of mission-critical communication. If line-of-business managers and others are out of the loop as soon as they step away from a desktop, that creates delays that make same-day manufacturing and shipping difficult. What if the customer wants a discount or if purchasing needs approval to purchase additional inventory at a premium to satisfy an order? Something as simple as the ability to receive notifications of emergent events and handle approvals while mobile can make to-order business models a lot more feasible.

What’s next for manufacturing ERP?

Seven years ago, ERP software was helping manufacturers prepare for what’s next. Now manufacturers are ready for the more agile manufacturing business models of today. But how are manufacturers preparing for the next round of digital transformation? How are they preparing for what’s next? Find out by downloading the study, How Digital Transformation is Changing Manufacturing.

Do you have questions or comments?

We’d love to hear them so please leave us a message below.

Hitendra Singh Rathore

Hey Charles, great article. I always seek for the new trends and hot topics about the manufacturing ERP software. As I am too much fascinated about ERP software, Reading something new about it makes me feel great. thank for sharing such a valuable information