Is blockchain the answer to total traceability and transparency?

Traceability, recall, and risk

Hardly a day goes by without another recall or food scare, today it’s farmed liquid egg whites yesterday it was scotch eggs and kebab rolls. In fact, in USDA market research they declare that there is a recall every three days. Traceability is still one of the biggest reasons for the implementation of software solutions into the food and beverage industry and it’s easy to see why. The costs and penalties are catastrophic for a manufacturer who cannot provide the necessary traceability information in a timely manner, remember Perrier? – Perrier recalled 160 million bottles from 120 countries at a cost of over $250m.

No matter which area of the food or beverage processing industry you are involved in, the importance of traceability has never been greater. It’s important not just because of recent high profile scares, but because of the requirements put in place by retailers–after all it is their name, not yours, that gets plastered across the media when a food scare occurs.

When it happens, speed is of the essence. If you cannot give complete confidence in the accuracy and granularity of your traceability information, all your products will be removed from the shelves, at your cost, not to mention that you may be excluded from the next range review and a fine will almost certainly be imposed. More importantly the longer it takes to identify affected batches, the greater the risk to the public and the more widescale the recall.

What does the legislation say?

We all assume that the legislation will be on the side of safety but is that true? For example, the EU Regulation 178/2002 lays down the general principles and requirements of food law. It requires every food and beverage business in Europe to have a traceability and recall system in place and states:

“All food and feed businesses must be able to identify where their raw materials (e.g. ingredients and packaging) come from and where their products are going or have gone to, i.e. they must be able to identify one step back and one step forward in the food chain.”

What’s missing from this requirement is the TIME dimension. The British Retail Consortium (BRC) in its audit requirements states that “Traceability should be achievable within 4 hours.” Why is the word ‘should’ in there? In my mind, with modern technology and integrated ERP solutions available to manufacturers, traceability can be achieved in minutes. Recall information can be obtained at the press of a button, but it often takes days for the recall to unfold.

One could understand the missing time dimension if there was no risk to human health, but there is and the new BRC standard includes changes that only go to reinforce that the risk is real. It’s not just contamination if we layer on top allergy reactions, pathogens and dare I say bio-terrorism the need to be able to react immediately is vital.

But how do you inform the millions of people who may have purchased a contaminated product? Currently, it’s displayed as a recall notice when you visit the store or watch/read a media article.

New kid on the block(chain)

ERP solutions have been providing end to end traceability for tens of years but now blockchain is being held up as the savior. Recent articles on the subject use phrases like “Blockchain to revolutionize traceability” and “Improved food safety with Blockchain” but will it really and what advantage over a modern ERP solution does it have if any?

ERP advantages

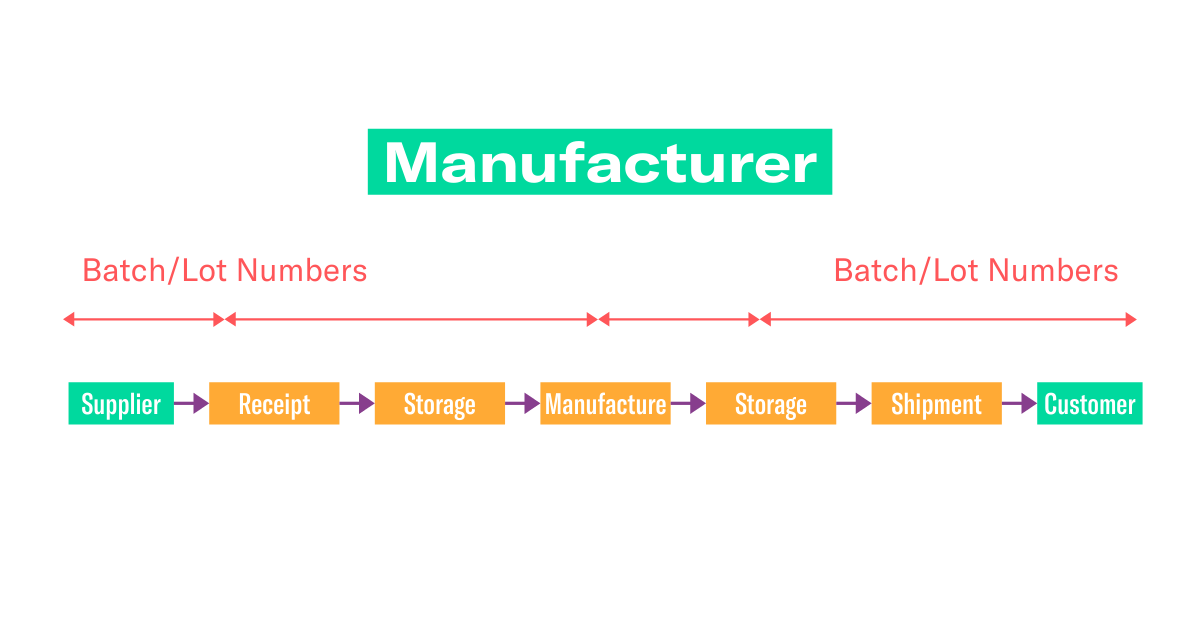

- ERP systems use the transactional movements of lots/batches to generate traceability records without the need to integrate or export this data to a blockchain.

- ERP systems offer traceability effectively free of charge.

ERP disadvantages

- The track and trace data is only “one up one down” e.g. from supplier to customer, so to tracking through multiple steps in the supply chain requires information to be passed from one solution to another.

Blockchain advantages

- The data is unalterable and cannot be changed, so potentially more secure, but this may also be a disadvantage (see below).

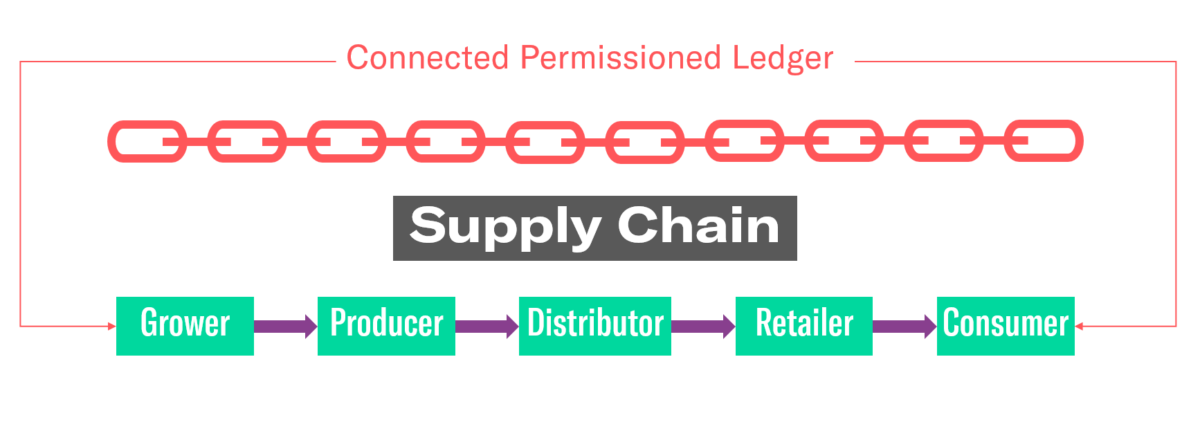

- The chain could extend beyond “one up one down” linking all steps in the supply chain, however, this would require agreement by all parties involved, each adding their own data onto the chain. This idea sounds incredible, my fridge could tell me in real-time that my pizza was on recall. However back in the real world, if Blockchain were to provide a better solution than is currently available then everyone in the supply chain must take part. One party not agreeing makes the chain useless and unfortunately, that is the most likely outcome.

Blockchain disadvantages

- The data is unalterable so if a mistake were to be made the chain would be corrupt, in an ERP solution, mistakes can be corrected.

- Blockchain would add additional cost and complexity.

Conclusion

Blockchain could offer the ultimate global traceability solution and the ability to track and trace up and down the supply chain across companies, supply chains, and countries. But that would require global collaboration, so I don’t think my fridge will be warning me just yet!

If you enjoyed this blog then please lookout for more at IFSBlogs.

I welcome comments on this or any other topic concerning process manufacturing.

Connect, discuss, and explore using any of the following means:

- Twitter: @ElkinsColin

- Email: colin.elkins@ifs.com

- Blog: http://blog.ifs.com/author/colin-elkins

- LinkedIn: https://www.linkedin.com/in/colinelkins

Michael Hawkins

You’re right that Blockchain on its own is a poor tool for implementing solutions on. However, there are an emerging set of technologies built on top of Blockchain, commonly known as Level 2, that help to provide additional functionality like revokation and updating whilst preserving the Blockchain s main strength of an immutable, decentralised, trust minimised and verifiable transaction database. A huge community is growing around decentralised identifiers (DIDs), much of the focus is on personal identifiers but it’s also a good fit for the supply chain use case.