This is one of a series of live blog posts directly from the site of the 2013 IFS World Conference in Barcelona. Business journalist Adam Tinworth is a veteran of Reed Business Information and a lecturer on digital journalism at City University in London. His first-hand impressions are accompanied by illustrations of Matthew Buck, cartoonist for Drawnalism.

IFS’s Peter Cornelius gives an insight into both the current state of IFS Applications 8 in the manufacturing sector and what we can expect from future Enhancement Packages and core updates.

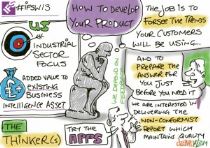

How does IFS develop its product?

How does IFS develop its product?

- We make some strategic decisions – they don’t do finance and banking, for example.

- We remain aware of IT trends and industry trends.

- We do our own research that leads to things like the our advanced visualizer technology.

- We consult with product reference groups in each region.

- We involve customers in the development process.

- We chose early adopters and work very closely with them.

This is a very, very important process for us.

The challenge for us is that we should be monitoring the trends, and developing for them before customers know they need them. Only by doing that will the tools be ready when the customers need them.

Augmented reality is one of Peter’s favourite trends. It takes a live image of an object of scene captured by a moil device, recognizes what’s in it and overlays useful data. One example is a live picture showing how to perform maintenance on the device you’re in front of. Devices like Google Glass will make this more mainstream and useful.

Manufacturing is part of the core processes that IFS like to support. How do we compete with larger players? We do it by focusing on exactly what we’re supporting.

Delivery Since Last Year

In the year since the last conference, they’ve delivered the Quality Assurance module – it was delivered with Applications 8 SP 1 and has been very successful. It allows you to monitor compliance to a fine level.

The Visualizer was an internal idea, developed with five reference customers. It’ll be delivered in a month’s time. ERP packages involve a lot of transactions – and good ways of accessing those. This was one solution – the other was a suite of BI Infosources, allowing you to do data analysis.

They’ve created Quality Assurance mobile apps. People have no problems downloading and using apps in their private lives. Why are companies so slow in adopting them? We have two solutions. One is the Audit Companion which allows you to take notes directly, and feed them into the system. Another allows mobile reporting of problems, along with photos of non-conformance. You don’t need to remember it – you just capture it then and there.

We wanted to extend the Sales Configurator B2B to allow for a worldwide network of partners. Say, you want to add a partner in Uruguay. You don’t want them to have direct access to the IFS system. What do you do? Use your new APIs to create a web app with your own branding that your partner can use.

Improved CBS/APB – helps improve the way we handle constrained scheduling systems – like sequencing orders, for example.

They also fixed more than 30 minor issues that the customers asked for – managing these tweaks in the paid update cycle is important to them.

Eco-Footprint 2.0 – catches your manufacturing data through materials bills. From the first of this year, there’s a national law that each EU country must implement forcing reporting of specific materials. This paves the way for doing that reporting easily.

Manufacturing Enhancement Package – 30 requests from customers available as an extension on top of SP1. Many fall into the planning and shop order fields. You can handle build of inventory, forecast consumption and run with MRP selections.

Shop Orders handle the switch of specifications in the middle of an engineer to order run, and handle the materials and schedule changes that arise.

Visualizer – What IFS wanted to do was move from tabulated data to a visual display. He believes that people are more receptive to pictures. They have the data – why not present it in a way that allows you to monitor it. There are graphs for materials, machine loads and so. They can be combined on a screen with an update at a determined schedule. But monitoring is not enough – you need to be able to take rapid actions on problems. One right click on the screen and you can do that – make purchase orders if you need to, for example.

Visualizer – What IFS wanted to do was move from tabulated data to a visual display. He believes that people are more receptive to pictures. They have the data – why not present it in a way that allows you to monitor it. There are graphs for materials, machine loads and so. They can be combined on a screen with an update at a determined schedule. But monitoring is not enough – you need to be able to take rapid actions on problems. One right click on the screen and you can do that – make purchase orders if you need to, for example.

It’s an out-of-the-box solution. It’s an add-on that sits next to any screen. And it’s designed for touch – you can run it on a pad whoever you are.

Manufacturing Info Sources

Four new sources. Additional production KPIs. Better costing tracking and analysis.

The development structure means that service packs are mainly bug fixes with a few enhancements. More specific extensions to the core service come in sector-specific enhancement packs, which you can add if you chose. This will be roll we rolled into the core with the next major update.

The Manufacturing Enhancement Package is in Beta and being tested by customers right now, and is due by the end of the year, as is the Visualizer.

The Next Core

What could you expect in the next version?

Manufacturing Excellence is one. Business changes – there is a constant need to improve on the existing product, and they want to keep on top of that. Visualization will continue to be developed – the release later this year is just the start. Strategic and tactical planning is going to become more important.

Project-based manufacturing is important. What did Mike Opal say on stage that you shouldn’t compete on price? Because you’ll always lose to China. Project-based manufacturing is one way people are finding success. We want to support that kind of business better.