Of the many contemporary challenges facing an industry like paint and coatings, supply chain management is a critical one at a time when industry trends point to strong projected growth across the board during the next few years as economies in major markets continue to recover from the recession.

My first contact with the paint and coatings industry was in the mid-nineties. I was assigned as the project manager for a multi-national roll-out of IFS Applications for a paint manufacturer. Since then I have been involved with paint and coatings manufacturers in different roles as consultant, sales support and in my current capacity as industry director for process manufacturing.

Consciously, and sometimes unconsciously, I have always wanted to understand what really matters to these companies when they select their future ERP solution, and use this understanding to help improve our own offering, IFS Applications, to become an even better option for these companies.

Of course, there are many aspects and perspectives to this. Some of them are generic in their nature (thus a bit less interesting to me specifically). This goes for application areas such as Finance or HR with similar requirements for any manufacturing company; or technologies for integration and user interaction.

These things matter, of course: seen from the customer’s perspective, they are usually as important as any industry-specific element that we can offer.

The specific ERP capabilities required for an industry is a consequence of the way companies in a particular industry operate. In the process manufacturing industry, for example, characteristics include:

- Compliance with environmental legislation, labor protection and quality standards is important.

- Manufacturing is formula based, usually in combination with a discrete filling and packing process creating a mixed-mode manufacturing environment.

- Raw material cost is high, manufacturing often asset-intensive, and the number of potential finished goods is huge.

- Multi-site supply chains that needs to be transparent and coordinated.

- Multi-channel sales where the customers may be automotive companies, retailers or plain distributors.

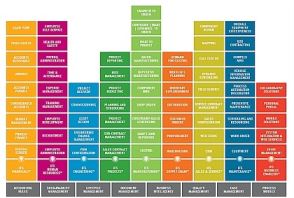

Each of these characteristics presents its own opportunities and challenges for ERP solutions like IFS Applications to address with functionality such as quality management, production planning, trade management and supply chain management – all designed to help companies excel in areas that are mission-critical to them.

In tandem with this, we offer all the capabilities you would expect from extended ERP. It is the possibility to combine industry-specific components with the general functionality part of an extended ERP that I believe is one of the most important reasons why a company should choose IFS Applications.

Most companies need generic solutions for CRM, HR and Finance. Others are specifically looking for capabilities such as Asset Management, Service Management or to plan and execute Projects.

With IFS Applications, you will get not only the industry-specific components that are necessary to conduct your business – you will also have the possibility to implement all other components included in IFS Applications. Since we are a one product company and develop all our solution on one single technology using a component based approach you can easily configure your solution according your current and future needs.

It is probably this combination of being able to scale to support the specific needs of a process manufacturer – and the scope offered by an extended ERP suite, all in one common technology – that matters most to our customers.

I’ve expanded my thinking on this big topic in “ERP: Primer Coat for the Paint and Coatings industry,” a new IFS white paper that’s available now for free download. It covers not only supply chain management but also other challenges such as high asset costs and utilization, environmental compliance, and more.

You may find it useful as you consider your plans in a recovering economy.